? Are we looking for a compact, reliable proximity solution in the security and access control category like the Hid Thinline Ii 5395Cg100 Inductive Sensor “Product Type: Security Devices/Security & Access Control Devices”?

Product at a Glance

We want to give a concise snapshot so we know what we’re dealing with before going deeper. The product listing identifies this item as an inductive sensor intended for security devices and access control systems, and the available description is minimal beyond that classification.

We should treat this section as our baseline summary: it orients us to the sensor’s role (metal detection/position sensing in access systems) and reminds us that more detailed specifications are often required for final purchasing or integration decisions.

What the Hid Thinline Ii 5395Cg100 Inductive Sensor Is

We understand that an inductive sensor detects metallic objects without contact by generating and monitoring an electromagnetic field. As the model name suggests, the Hid Thinline Ii 5395Cg100 is positioned in the security and access control device category, implying it is designed to integrate into gate controllers, door systems, electric locks, and related hardware.

We’ll treat this product as a small, application-focused sensor intended to provide reliable, low-maintenance metal detection for access control tasks, such as confirming actuator positions, detecting metal keys or tags, or integrating with locking mechanisms.

Key Features (Expected and Typical)

We want to highlight the features we expect from a typical inductive security sensor of this class so we can set realistic expectations. While the listing gives only the category, many inductive sensors share similar design and performance features that are relevant when assessing value and fit.

We’ll use this section to identify common traits like non-contact detection, immunity to many environmental contaminants, and durable housings. These expectations inform how we would plan installation and integration.

Typical Capabilities

We expect the sensor to offer reliable metal detection with rapid switching and stable outputs. Common capabilities include short sensing distances for precise position detection, robust environmental ratings, and simple electrical interfaces.

We acknowledge that specific electrical characteristics (e.g., PNP vs NPN output, supply voltage, switching frequency) are crucial to system compatibility, and we recommend confirming those before finalizing procurement.

Design and Build Quality

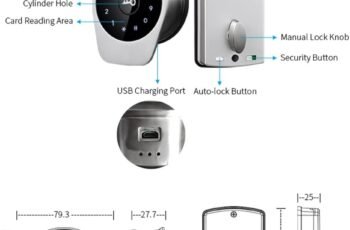

We like to know how a device is built because physical robustness matters in security environments where sensors often experience vibration, weather, and heavy use. The “Thinline” name implies a slim profile, which typically helps with discreet installations and reduced intrusion into mechanical designs.

We expect the housing to be rugged, likely metal or high-strength plastic, with threading or mounting options that make installation straightforward. Durability in the form of impact resistance and corrosion protection is usually important in access control contexts.

Form Factor and Mounting

We anticipate a slim, compact package that fits into narrow mounting slots or hangs inside housings without obstructing mechanics. That slimness tends to simplify retrofits and helps keep visible footprint low.

Mounting threads, brackets, or flanges are commonly provided or supported, allowing for both flush and non-flush installation depending on the application. We would plan for some vibration mitigation if the mounting location is subject to mechanical movement.

Electrical Interfaces and Outputs

We consider electrical compatibility a core part of the review because improper matching here is a frequent cause of integration trouble. Inductive sensors generally come with either 3-wire or 4-wire connections, and outputs are commonly NPN (sinking) or PNP (sourcing).

We recommend confirming whether the Hid Thinline Ii 5395Cg100 provides a normally open (NO) or normally closed (NC) output, and whether it needs DC or AC supply. These choices affect how it will interface with controllers, relays, and security panels in our systems.

Wiring and Connector Expectations

We expect the sensor to use a simple wiring scheme with color-coded leads or a standard connector for quick connection. In security environments, we like screw-terminal adapters or pigtails that are easy to route inside control cabinets.

If the device comes with an integrated cable, we’ll check the length and gauge to ensure it matches our installation layout, or plan for extension with proper shielding if needed.

Performance Characteristics

We prefer sensors that provide consistent switching, minimal false triggers, and stable operation across temperature ranges. Inductive sensors excel at detecting metal in a repeatable, contactless way, which makes them suitable for many access control tasks.

We will look for details such as sensing distance (typically a few millimeters to centimeters for small inductive types), switching frequency (relevant if the target moves fast), and hysteresis/response stability to avoid chatter in mechanical systems.

Sensitivity and Range

We expect short-range sensing intended for precise position detection rather than long-range metal detection. This precision is useful when we need to confirm the closing of a strike plate, detect the presence of a metallic actuator pin, or confirm gate latch engagement.

We will also consider whether the sensor sensitivity is adjustable or fixed. Adjustable sensitivity gives us more flexibility during commissioning, but fixed sensitivity often simplifies setup and reduces the need for on-site tweaks.

Environmental and Durability Ratings

Security devices often face dust, moisture, temperature extremes, and mechanical stress, so ingress protection (IP) ratings and materials matter a lot to us. Typical industrial-grade inductive sensors carry IP65, IP67, or higher ratings, and sometimes conformal coatings or stainless steel housings for harsh environments.

We will verify the sensor’s environmental ratings and materials to ensure it matches our deployment needs—whether that’s indoor cabinet use or exposed outdoor mounting near gates or barriers.

Temperature and Corrosion Resistance

We expect the sensor to be specified for a reasonable operating temperature range (for example, -25°C to +70°C in many sensors), although exact numbers must be confirmed. For outdoor or coastal installations, we favor corrosion-resistant finishes and seals.

We will plan for protective measures if the sensor lacks high corrosion resistance, such as positioning it within protective housings or choosing stainless alternatives when salty or chemically aggressive environments are expected.

Integration with Security & Access Control Systems

Integration is where these sensors earn their keep: they become the hands and eyes of access hardware. We anticipate that the Hid Thinline Ii 5395Cg100 is intended to interface with access control panels, door controllers, gate operators, or lock controllers through standard digital outputs.

We will look for compatibility with common controller logic levels and consider whether pull-up or pull-down configurations are required. We’ll also examine whether the sensor can be used directly to signal relay coils or whether an intermediate interface module is preferable.

Communication and Signaling

While many inductive sensors provide a simple digital switching output, some installations prefer sensors with diagnostic outputs or self-monitoring features. We’ll note if the device supports LED status indicators or fault signaling to speed maintenance.

We’ll also think about electrical isolation and whether galvanic isolation or optocouplers are needed to prevent ground-loop issues in complex access control installations.

Typical Use Cases in Security Installations

We find it helpful to think in use-case terms to evaluate whether a product fits our needs. Inductive sensors like this one typically help confirm latch positions, detect the presence of metallic keys or badges in some custom setups, or provide end-of-travel detection for sliding gates and barriers.

We’ll consider scenarios where a compact sensor is preferable: retrofitting an existing strike mechanism, discreetly confirming the position of a deadbolt, or monitoring metal safety switches near moving components.

Examples of Installations

We might use the sensor to confirm that a lock bolt has fully extended, to sense a metal actuator embedded in a movable panel, or to detect metallic parts of an automated barrier arm. When paired with the right controller, these sensors contribute to secure fail-safe or fail-secure behaviors.

We’ll plan for placement and alignment during commissioning, as slight misalignment or incorrect sensing distances can cause spurious signals.

Mechanical and Electrical Installation Tips

We believe a good product can be made great or frustrating depending on installation quality. Proper mounting, wiring, grounding, and strain relief are essential to achieve stable, long-term performance.

We recommend thorough planning of mounting position, using the correct tools to ensure the sensor’s sensing face is oriented per the manufacturer’s recommendation, and securing cabling against vibration or pinch points.

Commissioning Checklist

We suggest a short commissioning checklist we follow: confirm supply voltage and polarity, test output while moving a known metal target, verify LED status or diagnostics (if available), observe switching behavior under real load conditions, and document cable routing and serial numbers for future maintenance.

We also recommend recording the baseline behavior (switching times, target sizes, distances) to simplify long-term troubleshooting.

Diagnostics and Troubleshooting

We prefer sensors that give straightforward diagnostics so we can find and fix issues quickly. LEDs that indicate power, target detection, or fault states are very helpful, as are clear wiring diagrams and accessible reset or recalibration instructions.

When issues occur, we typically verify power, wiring continuity, target type and distance, and environmental obstructions before concluding the device is faulty.

Common Issues and Fixes

Typical problems include incorrect wiring polarity, incorrect output type selection, mounting too far from the metallic target, or cable damage. We handle these by re-checking wiring, swapping to the correct input type on our controller, moving the sensor closer, or replacing damaged cables with shielded alternatives.

If transient interference or chatter occurs, we often add a small RC filter at the controller input or enable hysteresis on the input if the controller supports it.

Safety and Compliance Considerations

We take compliance seriously because security hardware often falls under building or safety codes. While the product listing categorizes this as a security & access control device, we will check for applicable certifications like CE, UL, or other regional approvals depending on deployment location.

We will also check if the sensor meets electromagnetic compatibility (EMC) standards and whether the manufacturer provides safety documentation and product lifecycle support.

Locking and Fail-Safe Behavior

When used in locking mechanisms, the sensor’s role in fail-safe or fail-secure designs must be assessed. We’ll ensure our system logic accounts for sensor failure modes and that mechanical overrides or redundancies exist where necessary for safety or emergency egress.

We recommend designing the control logic so the sensor’s absence or fault condition triggers a safe, documented response rather than leaving the system in a potentially hazardous state.

Value, Availability, and Support

We judge value by how well a device meets requirements, the clarity of its specs, price, and the availability of technical support and spare parts. A sensor that’s inexpensive but lacks documentation or replacement availability can cost more over a system lifetime than a slightly more expensive, well-supported model.

We’ll evaluate vendor reputation, documentation quality, warranty terms, and how easy it is to source replacements or complementary mounting hardware.

Sourcing and Lead Times

In security projects, lead times can affect commissioning schedules. We’ll plan for potential back-ordering, and if this specific model is hard to source, we’ll identify compatible alternatives with documented cross-reference guides.

We’ll also look for distributors or manufacturers who provide clear technical datasheets and responsive support channels.

Pros and Cons (Practical Assessment)

We find it useful to summarize the main advantages and possible downsides so we can compare this sensor to alternatives quickly. Based on category and expected features, we can identify typical pros like reliability, compact form factor, and low maintenance, and cons such as limited sensing range or need for specific electrical compatibility.

We’ll use this section to help decide whether this model fits our particular application or whether we should look at other sensors.

Summary List

Pros:

- Likely compact, suitable for discreet installation.

- Non-contact detection reduces wear and maintenance.

- Typically robust to contaminants like dust and moisture when properly rated.

Cons:

- Listing lacks detailed specs, so we must verify electrical and environmental ratings before deployment.

- Short sensing range may limit flexibility in some mechanical setups.

- Potentially limited availability of installation accessories depending on vendor.

Comparison Table (Quick Reference)

We like having a table that distills the essential considerations for easier decision-making. The following table lists likely or typical attributes for an inductive sensor in this product category and what we should confirm before purchase.

| Attribute | Typical Expectation / Action |

|---|---|

| Product Type | Inductive proximity sensor for security & access control |

| Sensing Target | Metallic objects only (ferrous and non-ferrous with varying sensitivity) |

| Sensing Range | Short (millimeters to low centimeters) — confirm exact mm value |

| Output Type | NPN/PNP digital switch — verify which variant is supplied |

| Wiring | 3-wire or 4-wire — confirm connectors and cable length |

| Supply Voltage | Commonly 10–30 VDC for DC types — confirm exact range |

| Environmental Rating | Often IP65/IP67 — verify IP rating for outdoor use |

| Housing | Slim/thinline form factor — check material (metal/plastic) |

| Mounting | Threaded/captured mounting options — confirm accessories included |

| Diagnostics | LED status likely; verify indicator functions |

| Certifications | Check for CE, UL, RoHS as required for project |

| Typical Use Cases | Gate sensors, latch detection, position sensing in locks |

We will use this table as a checklist to compare the product against project requirements and to guide vendor questions during procurement.

Maintenance and Lifecycle Considerations

We aim for minimal downtime in security systems, so maintenance needs and expected lifecycle matter a lot. Inductive sensors are generally low maintenance, with no moving parts to wear, but seals, connectors, and cabling can degrade.

We’ll schedule periodic visual inspections, cable integrity checks, and functional tests during preventive maintenance cycles to catch issues before they affect security operations.

Replacement and Spare Strategy

For critical doors or gates we prefer to keep a small stock of matched sensors for quick swap-outs. We’ll record part numbers, vendor contact details, and configuration notes (wiring colors, mounting distances) so replacements can be installed without guesswork.

We also recommend labelling installed sensors with installation dates and initial test results to build history for long-term reliability tracking.

Final Thoughts and Recommendations

We want to summarize what this product likely offers and how we would approach using it in our projects. The Hid Thinline Ii 5395Cg100 Inductive Sensor appears to be a compact, security-focused inductive sensor suitable for typical access control tasks, and it should perform well when its electrical and environmental specifications match our installation needs.

Before committing, we will request the full datasheet and wiring diagram, confirm output type and supply voltage, verify IP and mechanical ratings, and ensure the vendor can supply spares and support. These checks make a reliable installation more likely and reduce integration risk.

Decision Checklist

We will proceed with this sensor if:

- The output type (PNP/NPN, NO/NC) matches our controller inputs or can be adapted easily.

- The supply voltage range aligns with our power supplies.

- The IP and temperature ratings match the environment where it will be mounted.

- The vendor supplies adequate documentation and reasonable lead times.

If any of these conditions are unmet, we will either ask the vendor for an alternate variant or select a sensor model with documented compatibility to avoid last-minute surprises.

How We Would Test It After Installation

We like to confirm behavior under realistic conditions after mounting. Our post-installation tests would include repeated actuation cycles with the actual metallic target, monitoring for false positives under environmental changes, and validating controller logic responses.

We will record the switching thresholds, any time delays, and long-term stability over multiple days to ensure consistent operation before sign-off.

Recommended Test Steps

- Power up and confirm LED or power indicator.

- Move the actual metal target into and out of the sensing area, observing switching behavior.

- Confirm controller receives and properly interprets the sensor outputs under load.

- Check for EMI or electrical noise impacts, especially near motors or relays.

- Perform temperature soak tests if the sensor will face extreme climates.

By following this testing routine, we ensure the sensor behaves as expected and contributes positively to the security or access control system’s reliability.

Closing Summary

We’ve covered the role, expected features, integration considerations, and practical guidance for the Hid Thinline Ii 5395Cg100 Inductive Sensor “Product Type: Security Devices/Security & Access Control Devices”. While the listing provides a category-level description, the sensor likely offers dependable, low-maintenance metal detection tailored for access control use.

We recommend securing the full datasheet, verifying key electrical and environmental specs, and confirming vendor support before deploying. With those details in hand and careful installation, this style of inductive sensor can be a dependable component of a secure access solution.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.